Instruction of shrink packing machine for gypsum cornices:

Make Ready

Line EPE foam along sides of cornices and tighten them by glue tapes. Then put gypsum cornices in a PVC film bag. Normally, 5 pieces of gypsum cornices can be in a bag. For larger sizes (more than 180mm width), 2 pieces in a bag is good.

Steps of operation

a) use three-pin plug to wired in to 220v AC supply

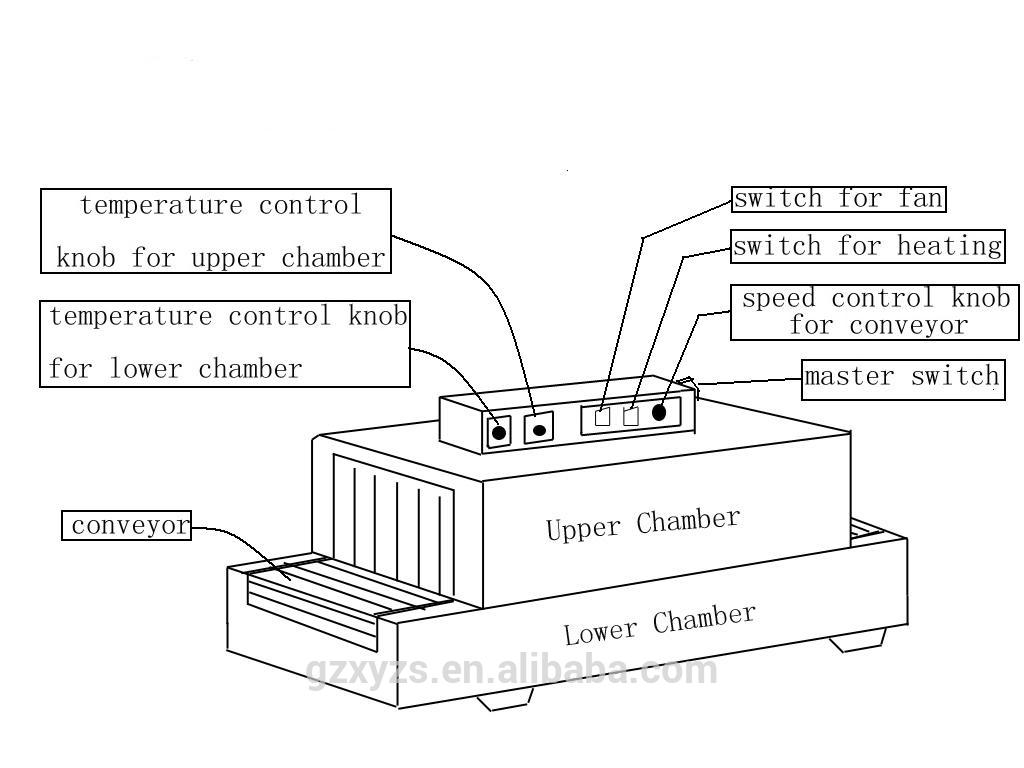

b) regulate the speed of conveyor to lowest; turn on master switch then turn on switch for fan; regulate the speed of conveyor to the proper one.

c) turn on switch for heating; regulate temperature of both upper and lower chamber to be 120 °C~180°C; After 10minutes , the chamber will be hot enough to start work.

(Explanation: If PVC film is tighten too much or broken, it means temperature is too high. You only need to regulate temperature of upper and lower chamber or the speed of conveyor)

d) after finishing work, please regulate temperature control knobs to be 0°C and turn off switch for heating first; take 5~10 minutes to cool the machine; turn off switch for fan then turn off master switch at last

e) for the sake of maintaining for conveyor, it is better to apply high temperature grease or premium engine oil to lubricate it every week.

f) temperature of chamber should be controlled below 230 °C and speed of conveyor should be controlled below 6 or 7 gear to increase in life span of machine

g) please keep bottom of machine in a cool, well-ventilated area to avoid electrical components to be superheating

h) please put the goods in the middle part as far as possible to avoid damage of quartz tubes in both sides of chamber